Introduction

In modern agriculture, precision and efficiency dictate the productivity and sustainability of farming operations.

Traditional seeding methods, while foundational, are fraught with challenges such as underseeding, which can significantly undermine crop yields, increase weed competition, and heighten susceptibility to pests and diseases.

A particularly disruptive issue arises with seed drill malfunctions, leading to uneven seed distribution and a plethora of subsequent agricultural complications.

Problem

Seed drill malfunctions, particularly those leading to under-seeding, can cause severe disruptions in crop uniformity and health. When a seed drill does not deposit seeds as planned, whether due to blockages, wear and tear, or calibration errors, it results in patches of a field being sparsely seeded or missed entirely.

This under-seeding compromises crop density, leading to poorer yields as plants do not compete effectively for sunlight, nutrients, and water. Over time, these inconsistencies can manifest in significantly lower production, directly impacting financial returns.

In scenarios where under-seeding occurs, it is crucial to determine the root cause of the malfunction—whether it stems from user error, such as incorrect settings or operational misuse, or from a manufacturer defect, such as faulty equipment or poor design.

Pinpointing the exact cause is imperative not only for rectifying the issue but also for financial considerations related to insurance claims.

Financial Loss

When seed drill issues result in financial loss due to reduced crop yields, having detailed and accurate records can be crucial. In insurance claims scenarios, evidence that pinpoints the nature of the malfunction can be critical.

If the issue is due to equipment failure, manufacturers may be liable, and insurance may cover losses depending on policy specifics. Conversely, if the problem stems from operator error, it may affect the outcome of the claim and highlight areas where training or operational adjustments are needed.

Addressing Malfunctions

Addressing these malfunctions traditionally involves manual inspections and troubleshooting, which can be highly labor-intensive. Farmers or field technicians need to walk through the fields, visually inspect the drills, and sometimes dig into the soil to check seed placement.

This process is not only slow and physically demanding but also subject to human error. Misjudgments in identifying or rectifying the issues can lead to further inefficiencies and increased costs.

Moreover, manual inspections cover only a limited area and might not accurately represent the condition of the entire field. This approach can miss underlying or sporadic problems, leading to unresolved issues that continue to affect crop performance and, ultimately, the farmer’s bottom line.

Drone Technology Solution

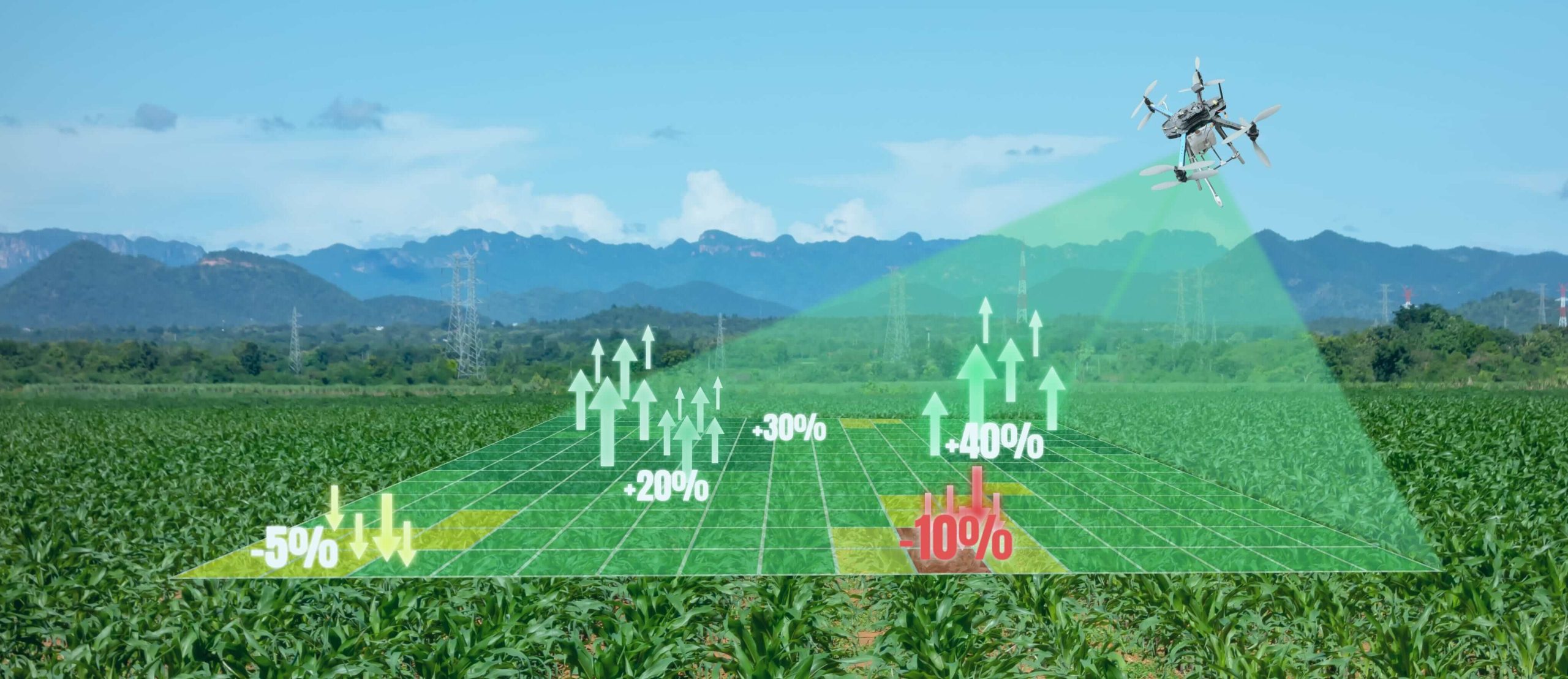

Enter the use of drones— a transformative solution that leverages cutting-edge technology to diagnose and resolve issues such as seed drill malfunctions with unprecedented precision and efficiency.

This case study focuses on a real-world application by Iprosurv, a company specializing in drone technology, in response to a malfunctioning seed drill in a large wheat field.

Incident Overview

A large wheat field had been compromised due to a seed drill malfunction, jeopardizing the crop yield and the farmer’s economic outlook.

A large wheat field was compromised due to a seed drill malfunction, putting the entire crop yield and the farmer’s financial stability at risk.

With a long summer ahead, the farmer needed to act quickly and re-drill the field to take advantage of the optimal growing conditions, which could potentially secure the financial returns necessary for his livelihood.

However, before re-ploughing and re-seeding could begin, the insurance company required detailed information about the malfunction and its impact on the field. This delay posed a critical challenge, as the timing of re-seeding was crucial to maximizing the chances of a successful harvest.

Iprosurv was promptly called upon to address this urgent issue using their advanced drone technology.

Drone Deployment and Data Collection

Upon deployment, Iprosurv’s drones equipped with state-of-the-art sensors quickly covered the vast field, systematically capturing high-resolution images and data.

Data Analysis

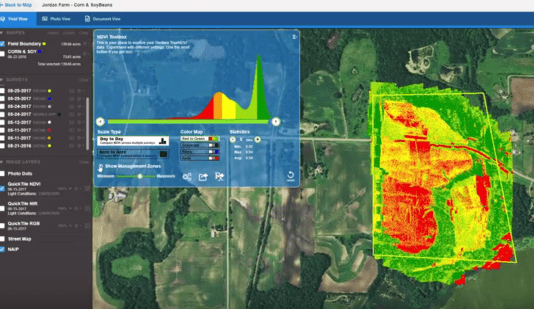

The comprehensive data collected by the DJI Mavic 3 Multispectral imaging drone allowed for precise quantification of the underseeded areas. This drone utilizes advanced multispectral imaging technology, including multiple sensors that capture data across various wavelengths, such as visible light, near-infrared, and red-edge bands.

These sensors are specifically designed to detect variations in plant health, soil composition, and vegetation indices such as NDVI (Normalized Difference Vegetation Index), which are critical for assessing crop conditions.

This information was crucial not only for understanding the extent of the underseeding problem but also for identifying specific areas of stress, nutrient deficiencies, or pest infestations.

By leveraging this data, farmers can plan necessary corrective actions more accurately to mitigate the impact on crop yield, optimize resource use, and enhance overall farm productivity.

Comparative Analysis: Traditional vs. Technology-Led Methods

Traditionally, addressing these malfunctions involves manual assessments which are both labor-intensive and time-consuming.

Farmers or technicians must physically inspect the seed drills and the field, often requiring them to walk extensive distances and manually dig into the soil to verify seed placement.

This approach is fraught with potential inaccuracies due to human error and the subjective nature of visual assessments. Moreover, such manual checks are sporadic and sample-based, potentially missing broader systemic issues with the seed drills.

Benefits of Drone Use

- Efficiency and Speed: Drones completed the field assessment in a fraction of the time it would take manually, swiftly providing essential data to stakeholders.

- Accuracy: High-resolution imagery and precise mapping highlighted specific problem areas that needed attention, allowing for targeted interventions.

- Cost-Effectiveness: Reduced need for manual labor and the ability to quickly address issues lowered the overall cost of managing the seed drill malfunction.

- Safety: Drones eliminated the need for physical field traversals, reducing the risk to human operators, especially in large or hazardous areas.

Impact

The rapid response and detailed analysis provided by Iprosurv’s drones were instrumental in facilitating a swift resolution. The data enabled the farmer to make informed decisions about reseeding strategies and allowed insurers to assess and process claims accurately, ensuring that financial losses were minimized.

Conclusion

The application of drone technology in identifying and resolving seed drill malfunctions represents a significant advancement in agricultural practices.

As this case study illustrates, drones not only enhance the capability to address specific agricultural challenges but also promise a future where farming operations can be managed with unprecedented precision and efficiency.

This technological evolution is set to redefine the landscape of modern agriculture, driving it towards more sustainable and productive horizons.