Enhance Efficiency, Detect Flaws, and Prioritise Safety

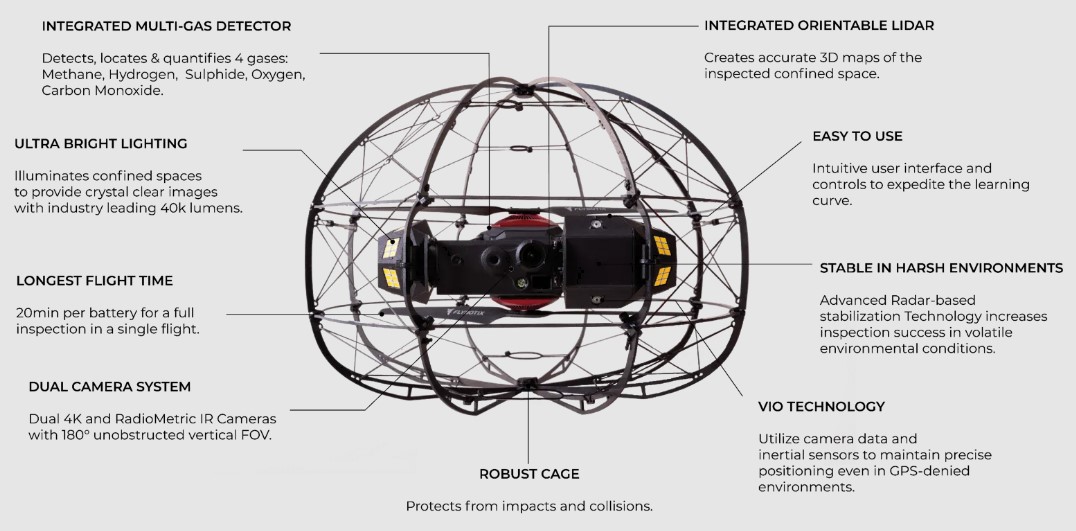

Designed specifically for indoor inspection, the Flybotix ASIO X is equipped with advanced sensors and cameras that allow it to navigate and inspect even the most complex environments.

Its compact size and agile manoeuvrability enable it to access tight spaces and hard-to-reach areas, significantly reducing the need for human intervention and minimising the risk of accidents.

This cutting-edge technology ensures that safety remains at the forefront while optimising operational efficiency.

1. Flight Stability:

One of the standout features of the ASIO X is its advanced flight stabilisation system, which guarantees smooth and stable flight even in turbulent conditions.

This stability is crucial for capturing high-quality data and images, especially in environments with limited visibility or potential obstacles. The drone’s sophisticated sensor suite ensures it remains level and steady, making it reliable even in dark, dusty, or debris-filled spaces.

2. Longest Flight Time:

The ASIO X boasts an impressive flight time of up to 20 minutes, which is one of the longest in its class. This extended flight duration allows for comprehensive inspections without frequent interruptions, enhancing productivity and reducing downtime. The drone’s unique propulsion system and ultra-lightweight design contribute to this extended flight capability, making it an ideal tool for prolonged and detailed inspections.

3. User-Friendly Operation:

The ASIO X is designed with the user in mind, featuring an intuitive interface that makes piloting the drone easy, even for beginners.

This reduces the reliance on expert pilots, saving on training costs and enabling a broader range of personnel to perform inspections. Its robust design includes a protective cage that guards against impacts and collisions, ensuring durability and minimising repair costs.

4. Powerful Lighting System:

Equipped with a 40K lumen lighting system, the ASIO X offers unparalleled visibility in the darkest and most confined spaces. The wide beam of light uniformly illuminates the inspection area, eliminating shadows and dark spots, allowing inspectors to detect even the smallest defects such as cracks or corrosion. The adjustable lighting system can be customised to suit specific inspection needs, providing flexibility and precision.

5. Integrated Gas Detection:

Safety is paramount during inspections, and the ASIO X excels in this area with its integrated gas detection payload.

This feature allows the drone to quickly identify and monitor hazardous gases like H2S, CO, and O2, protecting workers and ensuring a safer inspection process.

The high-accuracy sensors provide the most precise data available, allowing for informed decision-making in critical environments.

6. Robust Cage Design:

Designed with a robust protective cage, the Asio X is built to withstand impacts and collisions. This durability not only enhances the drone’s survivability but also significantly reduces repair costs, ensuring that operations can continue smoothly even after unexpected incidents.

7. Advanced LiDAR Capabilities:

For those requiring detailed 3D mapping of inspection areas, the ASIO X is equipped with a LiDAR system that delivers precise and comprehensive mapping, particularly useful in tunnel-like or confined settings.

This feature enhances planning, navigation, and data analysis, making the ASIO X an indispensable tool for industries needing meticulous environmental mapping.

8. AI-Driven Analytics and Asset Management:

The ASIO X is complemented by ASIO Explore and Connect, an AI-powered platform that streamlines inspection data workflows.

This platform leverages AI to automatically detect and classify defects, freeing inspectors to focus on critical decision-making.

It also supports seamless team collaboration with unlimited user access, secure data storage, and easy sharing capabilities, ensuring that inspection data is both accessible and actionable.