Introduction

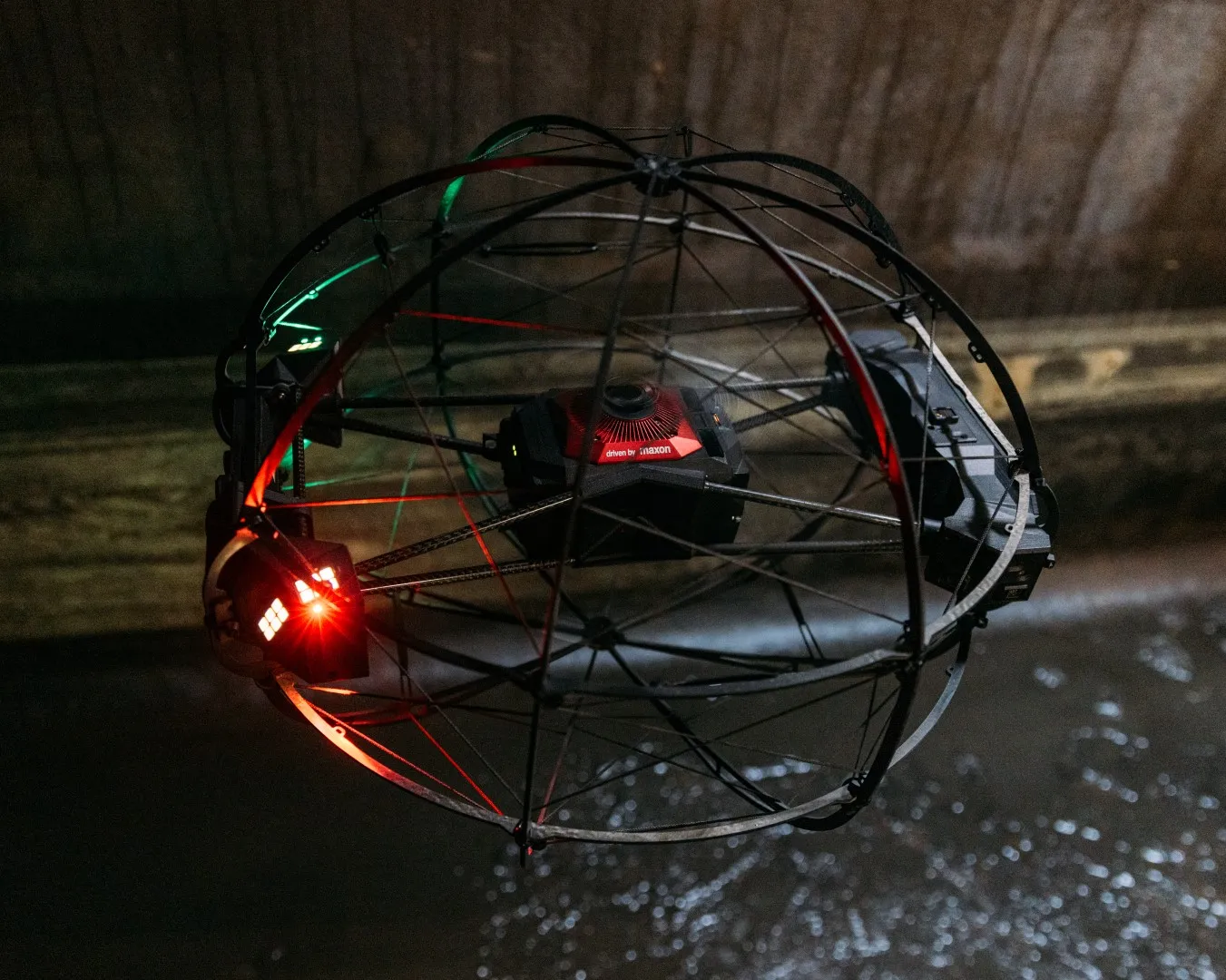

In the realm of industrial inspection and safety, the utilization of specialist internal inspection drones has emerged as a transformative solution for navigating challenging environments such as confined spaces, restricted areas, and contaminated sites.

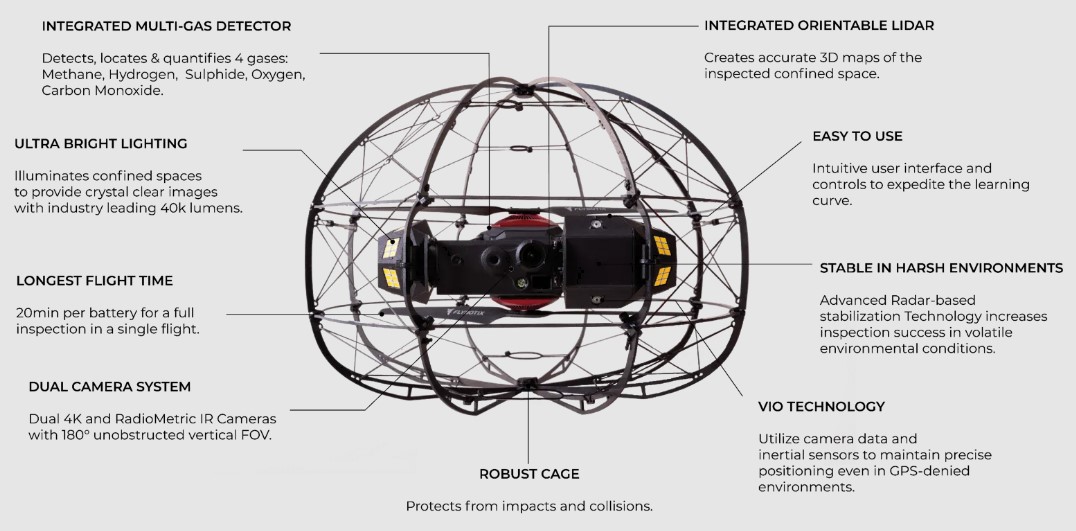

Equipped with advanced technologies, including onboard lighting systems, RGB cameras, thermal cameras, and LIDAR sensors, these drones are purpose-built to delve into spaces deemed hazardous or difficult to access by traditional means.

From the intricate internals of digestors to the complex infrastructures of nuclear sites, culverts, and other confined spaces, these unmanned aerial vehicles play a pivotal role in enhancing efficiency, reducing risks, and providing unparalleled insights.

By seamlessly maneuvering through intricate structures, these drones enable precise data collection, ensuring a comprehensive understanding of conditions within these environments without compromising human safety.

Confined Spaces

Confined space inspection drones represent a groundbreaking advancement in industrial safety and data acquisition, effectively mitigating health and safety risks while providing invaluable insights for enhanced decision-making.

These drones navigate through challenging environments such as digestors and culverts, where human access is limited and hazardous. Equipped with cutting-edge LIDAR technology, these unmanned aerial vehicles facilitate the generation of dense point clouds, enabling the creation of highly accurate 3D models.

By employing such technology, stakeholders gain a comprehensive understanding of the structural integrity and conditions within confined spaces, leading to more informed decision-making. The data collected by these drones is not only instrumental in preventive maintenance but also enhances overall operational efficiency.

The interpreted data can be seamlessly integrated into software systems, fostering collaboration among multiple stakeholders and streamlining communication for more effective risk management and facility maintenance strategies.

Confined Marine

Confined space specialist drones have emerged as invaluable tools in the maritime industry, revolutionizing various aspects of inspection and maintenance processes.

From inspecting tankers to scrutinizing cruise liner funnels, these drones play a pivotal role in enhancing efficiency while significantly reducing health and safety risks for human workers.

In the realm of cargo hold inspections, engine room examinations, and ballast and fuel tank scrutiny, drones provide a non-intrusive and precise means of gathering data, mitigating the need for personnel to enter potentially hazardous spaces.

Additionally, these drones are instrumental in the inspection of port and ship-to-shore cranes, ensuring optimal functionality and identifying potential issues before they escalate.

The deployment of confined space drones also extends to security and surveillance applications, enhancing maritime safety. Moreover, these drones contribute to maritime search and rescue operations, demonstrating their versatility in emergency situations.

A notable success story is exemplified by DroneUp, which saved over 700 hours in ABS tank inspection with speacialist drones equiped with multiple sensors and lighting systems, showcasing the significant time and cost savings achieved through this advanced technology.

Furthermore, the integration of drones for drone-to-ship deliveries underscores their potential to streamline logistical operations in the maritime domain, marking a transformative era in marine industry practices.

Digestors and Silos

Drones have revolutionized the inspection process of industrial facilities such as silos (clarifiers) and digestors, offering numerous advantages and benefits.

Firstly, drones provide a safer alternative to traditional manual inspections, reducing the risk of accidents and injuries associated with sending personnel into confined or hazardous spaces.

They can access difficult-to-reach areas with ease, offering a comprehensive view of the entire structure.

Drones equipped with high-resolution cameras and sensors enable detailed and accurate data collection, facilitating early detection of potential issues such as corrosion, leaks, or structural damage.

This proactive approach allows for timely maintenance interventions, preventing costly downtime and extending the lifespan of the equipment.

Additionally, drone inspections are more cost-effective compared to traditional methods, as they require fewer resources and can be conducted more efficiently.

Overall, the use of drones in inspecting culverts, digestors and other possibly contaminated areas enhances safety, efficiency, and cost-effectiveness in industrial maintenance practices.

Nuclear Inspections

Confined space drones are proving to be invaluable tools in the inspection of nuclear facilities, where safety and precision are paramount. These specialized drones navigate through intricate and challenging environments within the facilities, accessing confined spaces that are often difficult for human inspectors to reach.

Equipped with advanced sensors and cameras, these drones meticulously examine components, piping, and structural integrity, providing real-time data and high-resolution imagery to operators outside the confined areas.

By employing confined space drones in nuclear facility inspections, operators can enhance overall safety by minimizing human exposure to potentially hazardous environments, while simultaneously improving the efficiency and accuracy of inspections.

This innovative use of drone technology contributes to the ongoing efforts to ensure the integrity and reliability of nuclear facilities, fostering a safer and more reliable energy infrastructure.